MAYER MAKES Engineering Resin Extreme Strenght

MAYER MAKES Engineering Resin Extreme Strenght

MAYER MAKES Engineering Resin is a dedicated 3D printing resin for mechanical prototyping, engineering and small batch production. It is incredibly tough and impact resistant compared to normal „tough“ resin. With built in curing indication by color.

MAYER MAKES Engineering Resin Extreme Strenght

MAYER MAKES Engineering Resin Extreme Strength

Available in 1kg Bottles

MAYER MAKES Engineering Resin is a dedicated 3D printing resin for mechanical prototyping, engineering and small batch production. It is incredibly tough and impact resistant compared to normal „tough“ resin. With built in curing indication by color.

Made in Austria and available at a very reasonable price compared to competing products.

You can download: SLICER PROFILES PDF PRODUCT SHEET MATERIAL SAFETY DATASHEETS at: https://github.com/mayermakes/Engineering-Resin/

MECHANICAL STRENGTH

Normal resin 3d prints are not suitable for mechanical prototyping and mounting as they cannot withstand the same forces as machined plastic or FFF printed parts.

MAYER MAKES Engineering Resin is specifically designed to act as rugged 3d printable mechanical prototyping material and final production material for small to medium batches.

MAYER MAKES Engineering Resin can be machined with common metalworking tools such as lathes, cnc mills and hand tools to ensure perfect fit to tight tolerances and allow for extremely fast iteration cycles.

PRO-MATERIAL THAT WORKS ON HOBBY MACHINES

Unlike other professional products, MAYER MAKES Engineering Resin can be used on almost all commonly available hobby grade resin based 3d printers. The needed slicer settings are very easy to adapt from standard resin profiles.

We supply our customers with tested slicer profiles for the most popular 3D printers. These profiles are also very good starting points to tune in the settings for other machines.

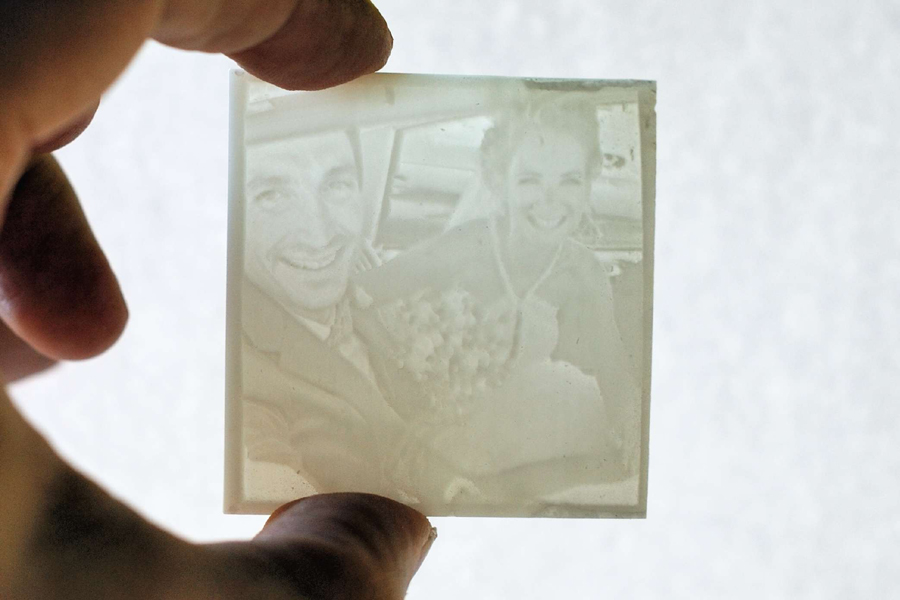

MAYER MAKES Engineering Resin has a built in visual curing indicator. The uncured resin is yellow, which ensures an ideal photoinitiated curing reaction with the UV spectrum commonly used by current resin based 3D printers.

BUILT IN VISUAL CURING INDICATOR

After the 3D printing process the part is washed and cured in a curing station as usual.

To ensure the best material performance the part is then cured in full spectrum UV light.

While curing this colorant dissolves until the 3D printed part turns clear.

This process works best in bright intense natural sunlight.

MIX AND MATCH

MAYER MAKES Engineering Resin can be coloured with standard resin colorants, while still retaining the color indication properties.

An uncured blue part for example would appear green until fully cured.

Mixing standard resins with MAYER MAKES Engineering Resin is encouraged and ideal to add toughness and impact resistance to any other 3d printing resin. Therefore enabling you to get the best price to performance ratio for your particular project.Support structures are best removed when they have turned clear, but the thicker portions of the model are still a bit yellow.

The difference in rigidity lets the supports easily snap off without much force right at the touching point.

This property and the high resilience to impacts makes the product perfect for 3d printable wargames and figurines that need to withstand frequent rough handling.